Bio-ARC: A Full-Stack System for Lab-to-Launch Biomanufacturing

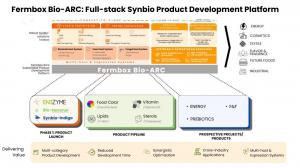

Fermbox Bio’s Full Stack Biotech Product Platform—engineering strains, enzymes, and processes to bring bio-based products to industrial scale.

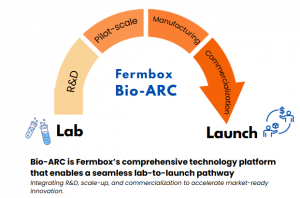

Bio-ARC brings together strain engineering, enzyme design, process development, and manufacturing into one adaptive system. It serves as a blueprint for moving biology from the lab bench to the production line. The name “Bio-ARC” reflects Fermbox Bio's mission to advance biology through new frontiers—a platform designed to translate biological ideas into large-scale applications and drive the shift toward a bio-based, low-carbon economy.

Why Bio-ARC? The Case for Integration

Bio-ARC is built on the principle of deep integration—where strain engineering, enzyme optimization, and process development are interdependent layers of a unified platform.

At its core, Bio-ARC enables early, system-level design of microbial production systems by co-optimizing host strains, enzymes, and process parameters. Microbial hosts are engineered with downstream compatibility in mind, ensuring each strain performs reliably in the lab and maintains yield, stability, and scalability in production.

The challenge with conventional synthetic biology lies in its fragmented development model. Strains are often optimized for narrow, lab-scale outputs—without real-time input from fermentation, recovery, or scale-up constraints. Enzymes may be engineered for peak activity under idealized conditions, but not within the metabolic or operational context of the host system. As a result, promising designs frequently fail during tech transfer, requiring costly rework or leading to complete project shutdowns.

Bio-ARC addresses this by collapsing those silos. By integrating strain and enzyme engineering with early-stage process insights, the platform builds a direct path from genetic design to manufacturable reality. It supports multiple microbial hosts—bacteria, yeast, and fungi—giving flexibility to match the right chassis to each product. Decisions made during strain construction are informed by the demands of scale-up—oxygen transfer rates, feed strategies, downstream recovery—all built into the design space from ideation. This unified approach speeds development, boosts consistency, and lowers the cost and risk of commercializing bio-based products.

Bio-ARC is a full-stack system built for industrial success:

Bio-ARC is built around three interconnected pillars that take a product from early design to industrial manufacturing.

1. Concept-to-Clone: This phase focuses on building the biological engine—production strains that are stable, high-performing, and optimized for scale. It includes both strain and enzyme engineering, with host systems selected based on product requirements and downstream compatibility.

2. Clone-to-Prototype: Strains and processes are refined at bench and pilot scale to ensure they are scalable and cost-efficient. This includes upstream fermentation, downstream recovery, and product isolation—resulting in prototypes that are ready for scale-up.

3. Large-Scale Manufacturing: The final pillar ensures that prototypes scale reliably into full-scale production. It includes tech transfer, scale-up optimization, and purification systems aligned with industrial requirements. Support extends to the design and operation of precision fermentation facilities, enabling a seamless transition from lab to commercial manufacturing.

Where It Delivers: Key Product Segments:

Bio-ARC powers sustainable innovation across multiple product categories, each targeting high-impact conventional materials:

1. Enzymes – Industrial and biofuel applications

2. Cosmetic & Nutraceutical Ingredients – Lipids for beauty and wellness applications

3. Colors & Dyes – Eco-friendly pigments for textiles and food

4. Flavors & Fragrances – High-purity aroma and flavor molecules

5. Sterols & Functional Ingredients – Health, wellness, and pharma applications

The first set of products from the Bio-ARC pipeline has already been announced—each at a different stage of commercialization:

1. EN3ZYME – A proprietary cellulosic enzyme blend for breaking down agricultural residues into fermentable sugars, enabling cost-effective 2G ethanol production.

2. BIO-HEXENOL – Fermentation-derived cis-3-hexenol with its signature “fresh-cut grass” note, used in flavors, fragrances, and cosmetics.

3. SYNBIO-INDIGO – A synthetic biology-based alternative to traditional indigo dye, reducing the environmental toll of dye production.

These innovations are being used across diverse industries—biofuels, food and beverage, personal care, textiles, and industrial manufacturing.

Why It Matters

The world is seeking better ways to produce everyday essentials—clean fuels, safer chemicals, sustainable textiles and more. As demand for greener solutions grows, Fermbox Bio is addressing it with biology that delivers at scale, with precision and purpose. Its platform, products, and people are aligned around a shared vision: unlocking the full potential of biology to build a cleaner, smarter, and more sustainable future.

Neelima Dandapat

Fermbox Bio Pvt Ltd

info@fermbox.bio

Visit us on social media:

LinkedIn

YouTube

Distribution channels: Energy Industry, Environment, Food & Beverage Industry, Manufacturing, Science

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.

Submit your press release